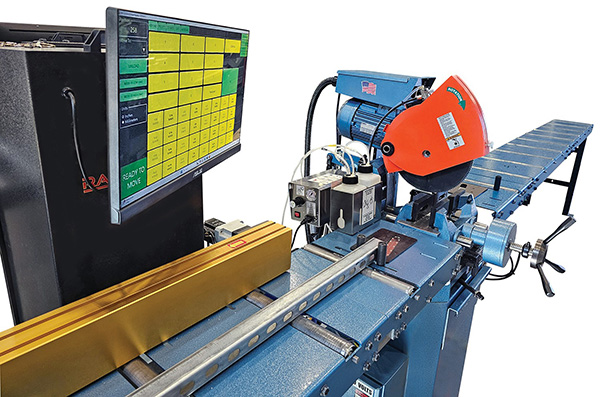

Scotchman Industries has introduced the CPO‑350 Automatic Cold Saw, a precision‑cutting system engineered to enhance accuracy, efficiency and workflow integration across metal fabrication environments. The CPO‑350 delivers fully automatic operation for cutting steel, stainless steel and non‑ferrous materials. Its automated material feed system improves repeatability and throughput while minimizing operator involvement.

Product details

A feature of the CPO‑350 is its ability to print directly onto metal tubing and profiles. Through BIM software and automation integration, the system can mark UPC codes, bend locations and hanger positions on materials such as Unistrut. This capability helps to streamline downstream processes, boost traceability and reduce installation errors.

Automatic CPO‑350 Cold Saw features:

- Fully automatic cutting cycle

- Air‑operated, double vise for burr‑free cuts

- Pneumatic power‑down feed with electric controls

- Manual miter capability from 45° left to 45° right with positive stops

- Double‑reduction, hardened and ground worm and wheel gearbox

- Integrated chip drawer

- Mist lubrication system

- Supplied with 315 mm HSS blade, blade wrench, and coolant

- Complies with ANSI B11.10 safety standards

- Two‑year parts warranty

- Made in the USA

What company leadership says

“The CPO‑350 was developed to help fabricators eliminate manual steps and improve accuracy from the shop floor to the job site,” says Mike Albrecht of Scotchman Industries. “By combining automated cold cutting with direct‑to‑metal printing, we’re giving customers a smarter way to streamline production and reduce costly rework.”