Edgy Ideas about IGUs

Acceptable appearance of insulating glass units’ edges

Excerpted from NGA Glass Technical Paper FB27-15 Considerations for the Appearance of Insulating Glass Unit Edge at the Time of Fabrication. For full details, download the complete document for free.

People who work with windows and doors often look at them instead of through them. Those who look closely may notice that the edge of an insulating glass unit appears differently depending on its materials and how it was made. For freshly fabricated vision and spandrel IGU edges, what visual variations are considered acceptable? How can the appearance be affected by the spacer, sealant and other factors? What industry resources and specifications are available? The following offers answers and additional considerations.

Sightlines and spacers

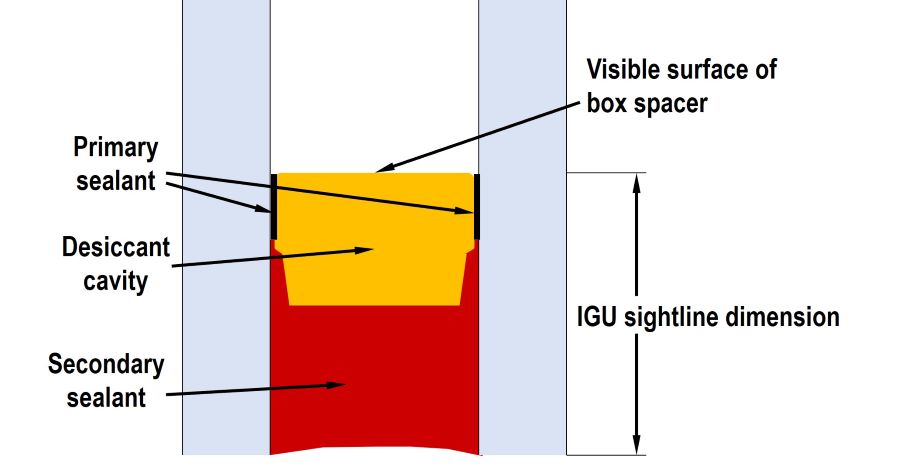

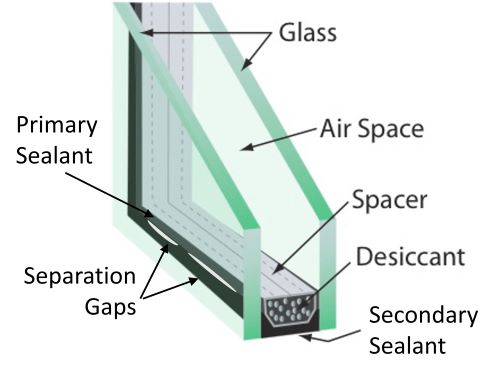

An IGU edge is the perimeter of an IGU. It includes the primary sealant, the secondary sealant and the box spacer. The vision area is bounded on all sides by the IGU sightline. This sightline is the distance from the glass edge to the visible surface of the spacer. IGU sightline dimensions may vary by up to 1/8 inch (3.2 millimeters) along any edge, and larger variations are common at the corners.

The top of the spacer and part of its side may be visible in some viewing conditions. Spacers come in different materials, finishes, textures, widths and colors. They may have IGU supplier information, certification labels, holes for gas filling, connection joints, and perforation holes or seams to allow for desiccant activity.

Variations in spacer color can affect appearance. Different spacer corner constructions also may be used on the same project. These differences are acceptable under industry standards. In structural silicone glazing applications, where IGU edges will be exposed to viewing, using a dark colored spacer may help conceal the spacer if the edge sealants do not fully cover it.

Sealants and separation gaps

The primary IGU sealant is usually applied mechanically on each side of the spacer and may extend beyond the IGU sightline into the vision area. The edges of primary sealants may be level with, above or below the top visible spacer surface. These are acceptable variations.

Primary sealant infringement within the as-fabricated IGU should not extend more than 1/8 inch (3.2 mm) past the sightline anywhere along the perimeter. Within 1 inch (25.4 mm) of the corner, the primary sealant infringement may exceed 1/8 inch (3.2 mm).

Both the primary and secondary sealants should be continuous and without voids. They are often different colors, which helps with quality checks. Selecting a spacer of similar color to the IGU sealants may minimize objections related to dissimilar colors. Be aware that gray sealant color may not be uniform, which is acceptable under industry standards.

A separation gap is the visible gap between the primary and secondary sealants where the spacer can be seen when viewed straight on. The gap width should not exceed ¹⁄₁₆ inch (1.6 mm), except within 1 inch (25.4 mm) of the corner. The total gap area should not exceed ¼ square inches (40.3 mm²). Any two gaps along an IGU edge should be at least 18 inches (457 mm) apart.

Because the silicone secondary sealant provides structural support in SSG applications, more sealant may be used than in captured units of the same size. This can result in varying sightlines on the same project. IGUs made with the lites intentionally offset may have secondary sealant that covers part or all of the offset edge. A mock-up or small sample is recommended as a visual reference. Discuss this with the IGU fabricator before production.

Edge deletion and other visual effects

Edge deletion is when the coating on glass is removed around the perimeter. Coatings are made of several layers, and removing them can cause changes in color, width and uniformity. It can also affect IGUs with offset edges. The primary sealant color in the deleted area may look different from the coated area. The amount of color difference depends on the coating and the removal method. Even if this difference is visible, it should not be cause for rejection. Viewing mock-ups is strongly recommended.

Edge deletion usually stops within the primary sealant area. It may extend up to 1/8 inch (3.2 mm) past the sightline, which could make it visible in the vision area. Different manufacturers may require different amounts of edge deletion. Contact the fabricator for details about the spacer system placement and tolerances.

Other variables affecting the apparent color of the IGU edge include glass substrate color, sealant color, glass thickness, applied coatings, silkscreened patterns, use of patterned or etched glass, viewing angle, and lighting conditions. For project-specific applications and concerns, contact the IGU fabricator.

The National Glass Association thanks our task group volunteers for developing this resource: Aaron Thompson, Task Group Chair, Viracon; Jon Griggs, Guardian Glass; Michael Speicher, H.B. Fuller; Melissa Szotkowski, Linel; Jason Fisher, Oldcastle BuildingEnvelope; Rick Wright, Richard E. Wright Associates; John Mayfield, Tremco Sealants; Robert Carlson, Tristar Glass; DJ Weil, Trulite Glass & Aluminum Solutions; David Cooper, Vacuum Glass LLC; and Steve Marino, Vitro Architectural Glass.