Implementing Innovation

These under-utilized products can help meet high demands for increased thermal performance

Editor's note: Technology such as that discussed in this article can help products meet today's increasingly stringent energy codes.

Window and door products are constantly being redesigned to meet ever-increasing thermal performance requirements and yet, there are many under-utilized products in existence today that could help meet high demands. Utilizing and leveraging these innovative solutions could reduce residential energy consumption while increasing homeowners’ thermal comfort.

Polyamide thermal barrier technology

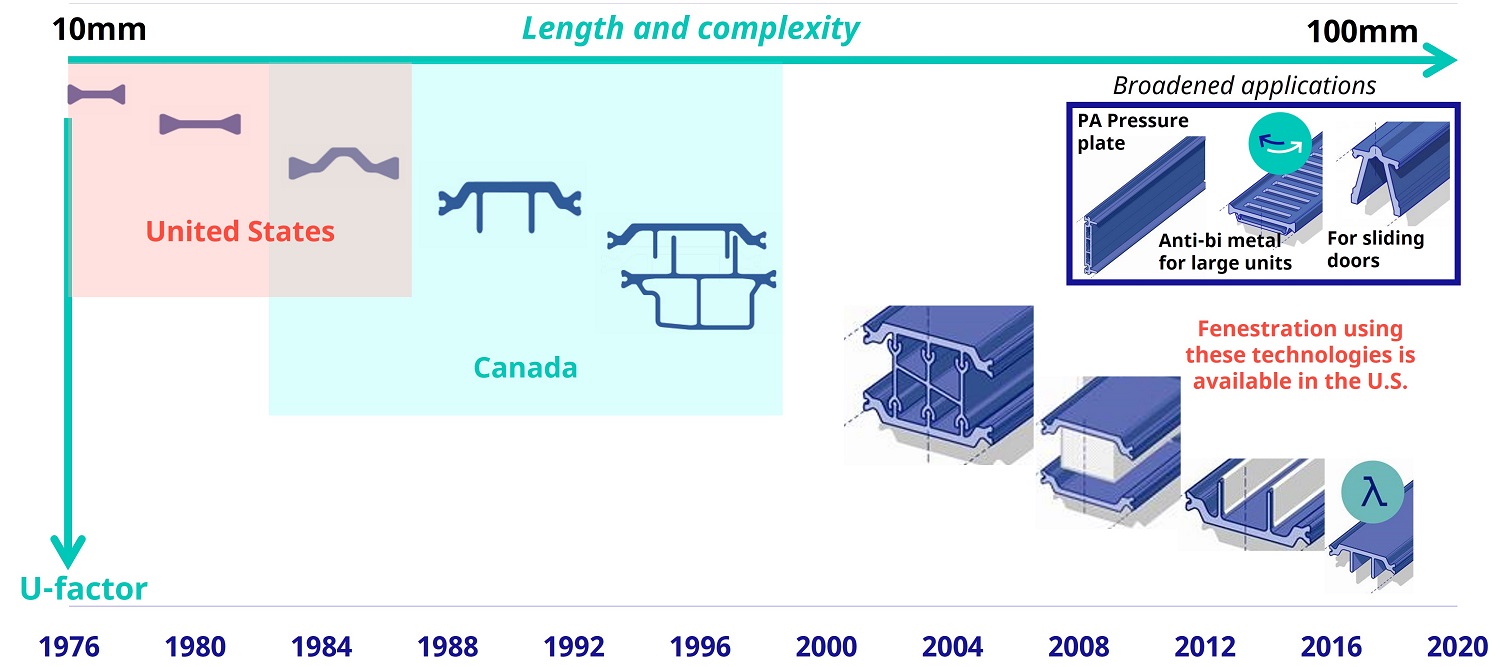

Polyamide (PA) thermal barriers is one technology that can have a major impact on the thermal performance of doors and windows. The graphic shows the evolution of PA thermal barrier technology for aluminum-framed window and door systems, which was first introduced in the mid-1970s. The initial barrier widths started at 10 mm and have now grown to see shapes as large as 100 mm.

Along with increasing barrier widths, PA profiles have become increasingly more complex. PA thermal barriers with legs were developed to break up interior cavities to reduce convective heat transfer. Later options applied foam to fill these cavities. New PA products also help reduce the effect of thermal bow experienced by large aluminum-framed doors using shearless PA profiles. More recently, low-emissivity foil has been used on PA barriers to reduce the smallest component of heat transfer—radiation—further improving thermal performance.

The latest technology involves a reduction in the thermal conductivity of the PA itself. This lower conductivity PA, referred to as “low lambda,” allows fabricators to achieve lower assembly U-factors in a given frame design without widening the barrier.

Availability and adoption

Above: The evolution of polyamide (PA) thermal barrier technology for aluminum-framed windows and doors. Credit: Technoform

The low-lambda material is already available and can be implemented in North American systems today. Many North American fabricators offer “R5” aluminum-framed windows (U=0.20 btu/oF.hr.ft2). High-performance, aluminum-framed windows utilizing 44-mm-wide PA thermal barriers and foam cavity fillers, achieving a U-factor as low as 0.16 btu/oF.hr.ft2, have been commercially available in the U.S. for at least five years.

Although fenestration systems with high-performance thermal barrier technology are available from many fabricators in the U.S., they are still not as prevalent as they are in Europe. Fenestration systems being used in typical U.S. homes still rely on PA barrier widths and designs first introduced 30 years ago (see graphic).

While the lower conductivity PA material has lower mechanical strength than regular PA, it typically doesn’t impact the fenestration design. The connection between the thermal barrier and the aluminum extrusion is often the limiting factor for structural performance. As a result, it may be possible to improve the performance of an existing design without changing extrusions, just by substituting the existing barrier with one made with lower conductivity PA.

More fabricators are adopting this thermal barrier technology to help meet high thermal performance requirements. Fabricators need a variety of tools to deliver lower U-factors across many different product types. Low-lambda PA provides another option to deliver the needed improvements in thermal performance while minimizing cost and simplifying manufacturing and supply chain complexity.