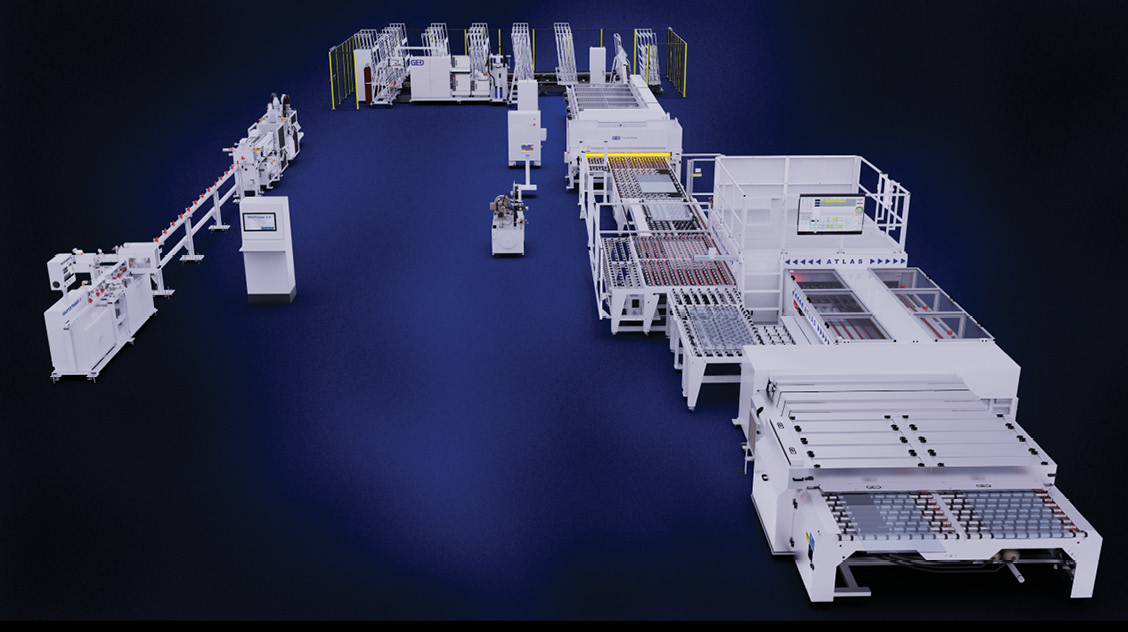

Product | Solution by GED

Intercept® Insulating Glass Line | GED Integrated Solutions

Challenge

Challenge

A window manufacturer in southern Ohio, already using equipment from GED Integrated Solutions, explored whether it could increase insulating glass unit production without disrupting the production schedule or adding capital expenses. This company wanted to get a better understanding of machine capabilities to boost productivity to keep up with sales growth and ensure enough work for all crews such as the assembly team.

Solution

GED Integrated Solutions, a worldwide supplier of fully integrated IG, vinyl window and door robotic automation fabrication systems, and software, discovered that this company produced about 800 IGUs over 10 hours. GED’s Intercept® Insulating Glass manufacturing capacity produces up to 2,880 units in an eight-hour shift. GED observed the process and shaped a plan with machine maintenance suggestions; operational improvement ideas, including loading glass into washers; and personal focused training such as floor instruction and effectively tracking metrics to ensure a steady pace.

Results

The capacity utilization changes helped the company begin its productivity journey and shorten lead times without increasing capital equipment costs. The window manufacturer more than doubled its IGU production to 1,920 units in an eight-hour shift. The company called the improvements “extremely successful.” These changes helped the company reduce labor costs by eliminating all overtime, saving the business over $300,000 per year.

Companies that increase productivity can improve profitability, limit breakdowns, affect job satisfaction scores and support the environment.

Learn more

For more information, visit gedusa.com or call 330/963-5401.