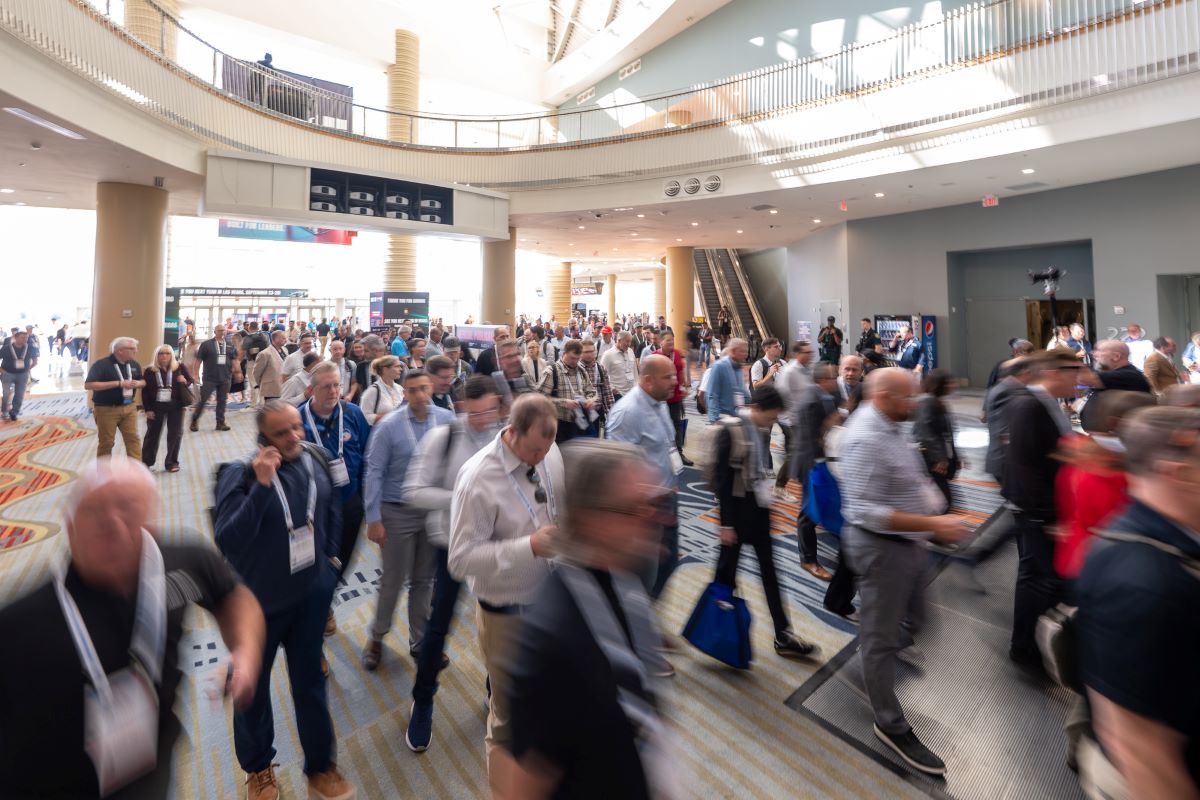

GlassBuild Brings the Industry Together and into the Future

The glass, window and door industries continue to innovate and collaborate

The future of glass and glazing was at the forefront of many conversations with those exhibiting at GlassBuild America 2025. From robotics to artificial intelligence, company leaders continue to innovate and automate. The 2025 show welcomed 589 exhibitors, of which 128 were new, and more than 9,600 participants over 232,600 square feet of exhibit space.

Trends in residential space

In the residential industry, the color black continues to show its strength in the window and door market. Veka launched its Obsidian all-black vinyl profile, and Deceuninck once again showcased its Eclipse all-black polyvinyl chloride profile. Rockwell Security, a door hardware supplier, has also found that matte black remains a top choice, while bronze and brushed nickel, previously popular, are slightly decreasing in popularity.

A NuCoat representative says that while black remains very popular, earth tones are also coming back. NuCoat creates coatings, primers and finishes designed for PVC, fiberglass, and aluminum and steel surfaces. New to this year, NuCoat is also dipping its toes in the door market by creating a topcoat for fiberglass and steel doors.

Quality Enclosures, a shower door manufacturer, says homeowners are asking for larger pieces of glass. A company representative reiterates that customers also increasingly want matte black hardware, as well as satin brass. “[Customers] also want companies that are transparent and offer a high level of service,” says the company rep.

Continental highlighted its exterior solutions, a market that laminate suppliers such as Continental and American Renolit are entering. Some of Continental’s laminate solutions have a shine to simulate high-end powder coat finishes. The laminate can go on vinyl or aluminum, and the Continental representative sees a demand for matching films on doors and windows for cohesive aesthetics. Continental’s machinery partner, Fux, can accommodate bending. The representative sees a big demand for shapes and bending equipment, especially in the replacement market, as people are replacing windows from the 1980s when bent shapes were popular.

Companies continue to meet consumer demand for better sightlines. Veka, for example, introduced its VuePoint single-hung window that can operate up and down or be placed sideways as a slider. The frame is mounted alongside the drywall, and the sash is encapsulated in the frame, making sash components invisible to give 23% more viewing area, as well as enhanced performance attributes.

Robotics and AI

Several companies showcased robotic solutions at GlassBuild. A collaborative trio—GED Integrated Solutions, Vitro Architectural Glass and Technoform—introduced the new Intercept Extreme warm-edge spacer system for high-performance residential windows. This next-generation system is a display of the power of partnership, and GED’s motto: intelligent automation. The new and improved system aims to solve manufacturing problems like volume of production, thermal performance and long-term durability.

Another partnership, Forel and Quanex, highlighted the innovative collaboration that is bringing automation and spacer performance to the next level. The new Forel Dura Line is designed to maximize output and optimize every stage of assembly. From spacer application to gas filling, it represents a new step forward in Forel’s insulating glass unit technology.

Billco Manufacturing featured its Robotic Arm, created in partnership with Kawasaki. It can manage loading and unloading throughout the factory. Salem Fabrication Technologies brought its AMR, or autonomous mobile robot, to GlassBuild. The glass-handling robot is also a result of a partnership with Kuka, a supplier of intelligent robotics. The low-to-the ground, square-shaped robot can lift and carry up to 1,200 pounds, say Salem reps. By reading QR codes affixed to a factory floor, the robot can then navigate its package to the next location.

AI has been a zeitgeist for several years now, and many people seem more comfortable using it in their own lives. Industry leaders say there’s still further to go in explaining how AI can actually become part of their business. A+W Software recently introduced Mira, its AI order-entry system, which can read in-bound emails, including attachments, and then use Gemini and ChatGPT to complete order entries.

Christian Weichelt, chief marketing officer of Cyncly, says he tries to demystify what AI can do for their customers’ businesses and discusses what’s best for their individual company. “They need to pace adoption, and to have a goal in mind first so that we can help them reach it,” he says. “It’s about using tech in an intelligent fashion.”

Automation aids in labor issues, helps homeowners

As many companies continue to grapple with a lack of skilled labor, automation and user-friendly additions are being added to machinery. RazorGage exhibited its AutoPusher System, which cuts fiberglass, wood and aluminum components. It is fully automatic in direct response to this need from customers. A company representative said they are also open to exploring the possibility of using robots for automatic loading and unloading in the future. “With the current state of the workforce, it’s increasingly important for customers to maximize yield, minimize mistakes and increase throughput,” he says.

Urban Machinery also expressed that automation is always something they are looking to increase with their machinery. While automating loading and unloading is difficult, they aim to create automated saws that help remove operator error.

A company representative for Pertici says, “Customers are always looking for user-friendly and intuitive” products and that “manufacturers like easy software” because employees working with machinery are not always skilled in that area. Rotox adds that customers need an easy and user-friendly interface. Matodi has also worked to create machinery that is user-friendly with pre-loadable templates to aid in the labor shortage.

Rockwell Security also recently added automation to its door hardware. Its new locking door hardware has an app connected via Bluetooth to help make home security easier for homeowners. A company rep says that “automation is a huge ask” among its customer base.

Tariffs and economic uncertainty

As tariffs around steel and aluminum still hang in the balance, companies are preparing for the impacts. While many are saying they are fortunate to not have felt the effects just yet, they are making sure to stay in constant communication with those in their supply chain to prepare for any future challenges.

A representative for Oz Machine said they have heard of some customers feeling the impacts of the tariffs, but many have tariff concerns written into their contracts with suppliers, so they are not being impacted too much this year. A company rep for TBP Converting says that not many people are building right now due to tariff and economic uncertainty. “When it comes to tariffs, it’s been coming in waves,” he says. “We’re just trying to meet our customers where they’re at.”